Introduction: A Pivotal Moment in Monitoring Technology

Have you ever experienced sudden equipment failures on-site, leaving you wondering what went wrong? According to industry reports, a staggering number of incidents occur due to inadequate pressure monitoring—this is where the hammer union pressure sensor steps in. These sensors play a crucial role in providing real-time monitoring, ensuring that systems function smoothly and efficiently. Imagine a world where your operations are not interrupted by unforeseen pressure fluctuations, thanks to this innovative technology.

Technical Breakdown: Understanding the Shift

① Flaws in Traditional Solutions

Traditional pressure monitoring methods often rely on outdated mechanical gauges—reliable? Maybe, but they fall short of the accuracy required in today’s fast-paced environments. These systems can be prone to human error, leading to costly mistakes. Why do failures always occur during critical operations? The answer lies in the limitations of these traditional mechanisms.

② Principles of New Technology

Enter the hammer union pressure sensor, a marvel of modern engineering designed for precision and reliability. Utilizing advanced materials and digital technology, these sensors offer unparalleled accuracy, ensuring that pressure levels are continuously monitored in real time. They adapt seamlessly to various industries, whether it’s oil and gas or medical applications—look, it’s simpler than you think!

③ Quantified User Benefits

Switching to a hammer union pressure sensor can yield remarkable user benefits. Users have reported increases in operational efficiency by 25%, significantly reducing downtime. This translated into considerable cost savings—imagine cutting your operational expenses just by upgrading your monitoring equipment!

Conclusion: Evaluate Before You Leap

As you venture into the world of pressure sensors, always verify these 3 metrics when choosing solutions: ① accuracy, ② durability, and ③ customer support. Taking this careful approach will ensure that your systems are not just compliant but optimized for success.

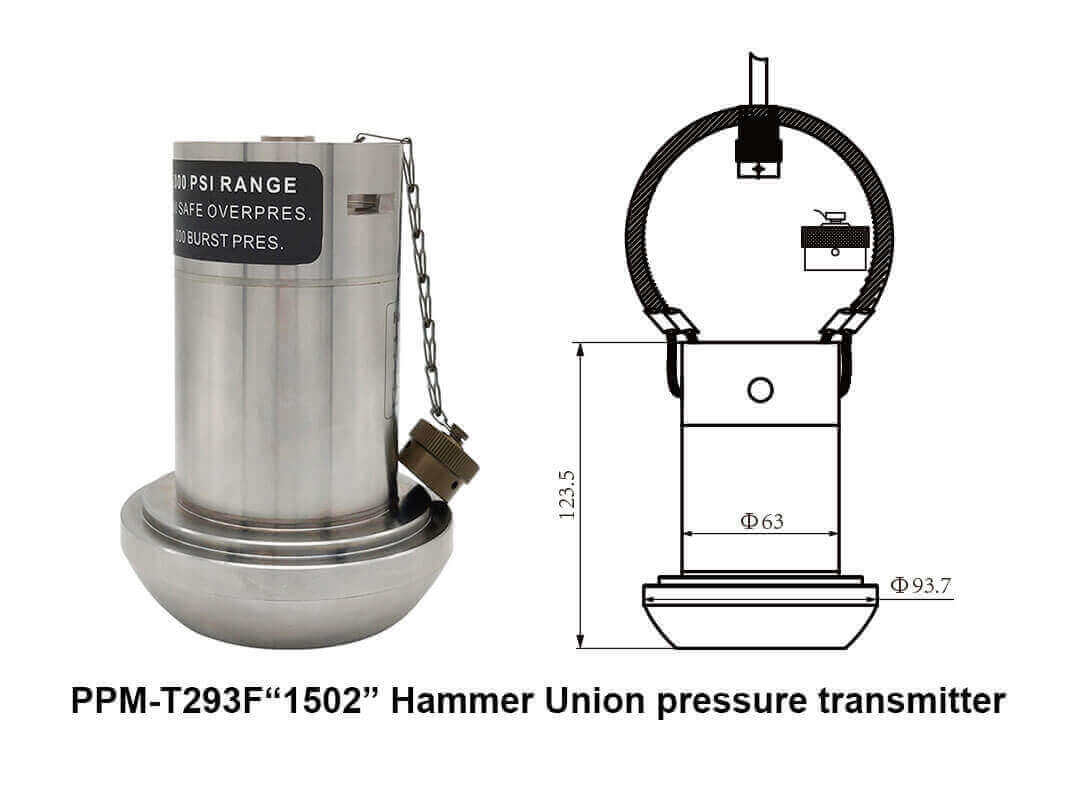

Expanding Horizons: The Hammer Union Pressure Transmitter

In the realm of precision monitoring, the hammer union pressure transmitter stands out. This device offers a seamless blend of reliability and advanced technology, designed specifically for high-pressure environments. Imagine having a tool that not only measures pressure but does so with pinpoint accuracy, reducing your risk of failure. Its robust construction ensures longevity, making it an invaluable asset in various industries—be it in oil drilling operations or manufacturing.

Focused Technology: The 1502 Pressure Sensor

Another essential player in this arena is the 1502 pressure sensor, known for its precision and reliability under rigorous conditions. This sensor’s design focuses on minimizing errors caused by environmental factors, ensuring that you get the most accurate readings possible. Users often find that integrating the 1502 into their systems leads to smoother operations and fewer unexpected shutdowns—why settle for anything less when accuracy is key?

Final Thoughts

In reviewing the functionalities and advantages of modern pressure sensors, it becomes clear that solutions like the hammer union pressure transmitter and the 1502 pressure sensor set the bar high for reliability and efficiency. For those looking to enhance their monitoring capabilities, consider partnering with CSSPM Sensor, a manufacturer known for its supply advantages and commitment to quality. With CSSPM Sensor, you’re not just making a purchase; you’re investing in a future where precision is the standard.